Consumer electronics experience rapid technological advancement, requiring prompt delivery of high-quality prototypes more than ever. The primary objective of design manufacturers pertains to developing innovative products, which they need to bring swiftly to market. The CNC machining process serves as the solution to meet industry needs. The supply chain management and minimized material usage through AI impairment have led to a 30% increment.

The former product manufacturing techniques are outdated. Because they take long hours and deliver imprecise product outcomes. CNC (Computer Numerical Control) machining reshapes industrial operations and standards. It enables companies to build realistic prototypes that serve as ready-to-produce designs. Consumer electronic sectors incorporate CNC machining as their essential tool to deliver modern devices that both appear superior and operate optimally.

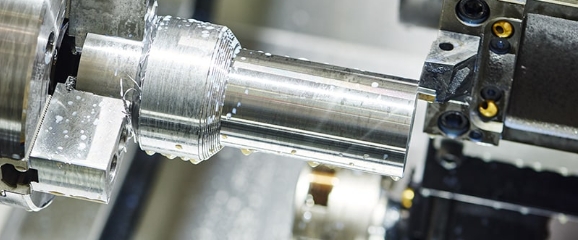

Why is CNC Machining a Game-Changer for Prototyping?

The CNC machining technology operates as a top-tier power tool dedicated to consumer electronics manufacturing. Its core elements include inch-precision alongside speed and repeatability. Due to these aspects, it has become vital during new product design testing. CNC machining distinguishes itself by certain factors. Let’s explore.

Insane Precision

Ever you know, how your smartphone fits together so meticulously? That’s CNC machining at work. The machines can operate on material dimensions below one-millionth of a millimeter by maintaining tolerances within + or – 0.01 mm. The machines deliver such precise accuracy that they produce perfect fittings of every button, as well as ports and internal components, to prevent expensive design errors before large-scale production starts.

Works with a Ton of Different Materials

The top advantage of CNC machining is that it handles all kinds of materials. From the high strength metals to soft and flexible thermoplastics, the machine can operate on all types of materials without limitation. The CNC process can successfully machine aluminum, titanium, high-grade plastic, and carbon fiber materials to develop prototypes. Consumer electronics benefit greatly from these astonishing features. Designers require tests on various materials to assess their impact on durability, weight, and heat resistance.

Super-Fast Turnaround

Customer service in electronic technology demands exceptional speed since companies compete to release new must-have gadgets, while prolonged prototyping durations result in lost business opportunities. The manufacturing process using CNC machines considerably shortens the time required to transform designs into operational prototypes. The creation of functional prototypes through CNC machining takes days rather than weeks when compared to standard production methods such as casting and injection molding. The role of machining mass customization permits companies to prototype personized designs.

How Consumer Electronics Brands Are Using CNC Machining?

The majority of electronic products at every scale, including industry leaders and upstart companies, use CNC machining to create their prototypes.

Smartphones & Tablets

Do you know the reason why top-line smartphones maintain their solid yet thin construction? The manufacturing process of aluminum casings and precise component tuning depends on CNC machining. CNC technology serves two essential functions: creating both camera housings and speaker grills and determining the placement of buttons. The flawless high-end designs that Apple and Samsung deliver to customers depend on CNC machining technology.

Wearable Tech

The modern market of wearable technology demands products that combine light weight with ergonomics and style alongside technological complexity. CNC machining processes the enclosure pieces, which produce a secure fit for your wrist and face space.

Gaming Consoles & Accessories

CNC machining serves as a preeminent manufacturing process for developing products in the gaming sector. Product durability and user comfort require precise precision engineering in the creation of controllers along with VR headsets as well as console casings. The production of new controller designs alongside the evaluation of trigger and button quality becomes possible through CNC machining before commercial manufacturing begins.

Challenges? Sure, But Solutions Are on the Way

Any technology system encounters obstacles despite its excellence. The high efficiency of CNC machining generates specific manufacturing difficulties during the production of consumer electronics. But the good news? The necessary solutions exist at present.

Material Waste

The major shortcoming of CNC machining occurs because the process uses subtractive manufacturing, contrary to additive processes. So, the manufacturing results in waste, particularly with expensive materials such as titanium and carbon fiber. Many manufacturers now put their money into AI-based machining systems, together with recycling programs to improve the usage of raw materials.

High Initial Costs

CNC machining proves to be a fairly expensive manufacturing solution at the beginning of your project. Acquiring both machine systems and skilled operating personnel costs significant funds. Companies experience cost efficiency through CNC technology since the process combines fast production speed with exactness, which avoids costly errors in future product stages.

What’s Next? The Future of CNC Machining in Consumer Electronics

Modern CNC machining technology will continue to improve because it shows no signs of disappearing. The upcoming developments will include:

AI-Powered Machining

Artificial intelligence signifies the intelligence of CNC machines. AI algorithms help machines forecast and fix errors in real time. This approach decreases operational expenses and improves operational processes. As per analytics, AI-driven predictive maintenance has increased equipment uptime by around 20%.

Hybrid Manufacturing

The deployment of CNC machining with 3D printing becomes a new company standard. Manufacturers use this combined method to build complex prototypes quickly. Because it merges leading features from subtractive and additive processes. Beyond that, it has significantly lower scrap rates. To quantify, it has decreased by 25%, leading to more efficient use of materials.

Miniaturization & Micromachining

The decreasing size of electronic components leads CNC machining to adapt to produce increasingly complex small parts. Manufacturers are developing advanced micromachining techniques. It enables the accurate cutting of the smallest PCB circuit board components.

Final Thoughts: CNC Machining Has Become Next-Gen Gadgets

CNC machining has become an indispensable technique and functional core in the consumer electronics industry. Each modern phone features, as do all tough smartwatches and strong high-tech gaming accessories, are now possibly developed through advanced CNC machining parts manufacturer. The technology allows companies to construct highly precise prototype versions of products rapidly, which helps shape technology development through its accurate cutting operations. Before reaching stores, all new devices undergo CNC machining to achieve their final perfection.

Media Contact

Company Name: Premium Parts Manufacturing Co., Ltd.

Email: Send Email

Address:Room 2008C, Block B, Zhongshen Garden, No. 20210, Caitian Rd, Fushan Community

City: Shenzhen

State: Guangdong

Country: China

Website: https://www.premiumparts.com/