Shop System Binder Jetting Enables Cost-Effective Batch Production of High-Quality 316L Stainless Steel Parts Via Additive Manufacturing

Desktop Metal (NYSE: DM), a leader in mass production additive manufacturing (AM) solutions, today announced it has qualified the use of 316L stainless steel for the Shop System™, the world’s first metal binder jetting system designed for machine shops. With an expanded materials portfolio, users can now leverage affordable, high-quality binder jetting technology to print end-use parts in 316L stainless steel with throughput, print quality, and productivity unattainable via legacy additive manufacturing processes.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20210824005530/en/

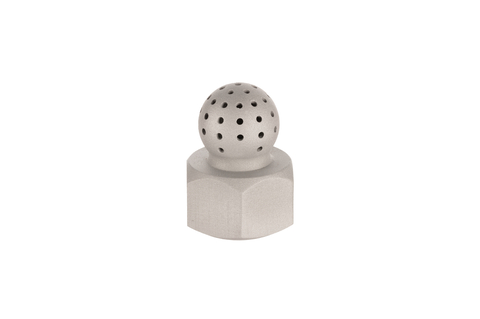

Custom spray nozzles are often used in chemical processing. With conventional manufacturing methods, such nozzles would typically be cast followed by extensive secondary machining on a five-axis CNC. 316L is an essential material for this part because of its excellent material properties, even at elevated working temperatures and while spraying corrosive fluids. 3D printing in 316L on the Shop System can produce the entire order of several hundred nozzles in less than a week with only one secondary thread-tapping operation required, reducing lead times and manufacturing process complexity. (Photo: Business Wire)

Known for its corrosion resistance, high ductility, and excellent mechanical properties at extreme temperatures, 316L is an austenitic stainless steel well-suited for demanding environments and applications, such as parts exposed to marine, pharmaceutical, or petrochemical processing, food preparation equipment, medical devices, surgical tooling, and consumer products such as jewelry.

“The launch of 316L for the Shop System is a part of an aggressive and extensive materials roadmap to broaden our AM 2.0 portfolio and address a rapidly expanding set of use cases for our print platforms,” said Jonah Myerberg, co-founder and CTO of Desktop Metal. “We are fully focused on developing opportunities for our customers to produce parts competitively with conventional manufacturing, and we are excited to be able to extend our binder jetting technology to meet this need and address key existing and emerging killer applications for 316L in the market.”

316L Stainless Steel - Key Applications

The Desktop Metal materials science team has validated that 316L stainless steel printed and sintered using the Shop System meets MPIF 35 standards set by the Metal Powder Industries Federation.

Examples of key use cases include:

-

Bulb Nozzle

Custom spray nozzles are often used in chemical processing. With conventional manufacturing methods, such nozzles would typically be cast followed by extensive secondary machining on a five-axis CNC. 316L is an essential material for this part because of its excellent material properties, even at elevated working temperatures and while spraying corrosive fluids. 3D printing in 316L on the Shop System can produce the entire order of several hundred nozzles in less than a week with only one secondary thread-tapping operation required, reducing lead times and manufacturing process complexity.

-

Watch Bezel

A bezel is the main component that houses the dial and movement within a watch. With the Shop System, multiple different watch bezel models can be printed in each build, enabling mass customization with no tooling required and minimal lead times. For consumer products applications such as this bezel, 316L is an ideal material since it allows for excellent corrosion resistance while maintaining the high strength.

-

Medical Device Closure

Assembly closures can be used to latch and hold medical device components in place. CNC machining these closures would be challenging given the miniscule, precise geometries, while metal injection molding (MIM) would require large investments and lead times for tooling, difficult to justify given the mid-volume requirements for the component. The Shop System can print up to 10,000 medical device closures in a week, without any tooling costs and without the extensive labor costs and time that machining would require. 316L is an ideal material for medical components such as this closure, because of its corrosion resistance, which makes it easy to clean and sterilize.

“Wall Colmonoy is excited to have 316L as a new option for the Desktop Metal Shop System,” said Michael Shreeve, Business Development Manager, Precision Components, Wall Colmonoy Limited UK, a global powder and components manufacturer. “We look forward to opening up the additive route to many more customers and component types. This will be of particular interest to our customers as we support them with maintaining supply chains across a wide range of industry sectors, such as petrochemical, power generation, automotive, aerospace and more. As we build upon our existing expertise with wear-resistant alloys such as Colmonoy® and Wallex®, 316L on the Shop System will be a welcome addition to our additive manufacturing portfolio of materials.”

“Availability of 316L stainless steel on the Shop System is excellent news, both for us and our customers,” said Patrick Chouvet, CEO of EAC Metal Ornaments, a renowned French-based metallic ornament manufacturer of worldwide designer collections in footwear, leather goods, apparel and cosmetics. “Some of our customers and applications require the excellent corrosion resistance the steel offers, and it is particularly well suited to the polishing and plating processes we use for luxury goods.”

The Shop System - Affordable, Batch Production of Metal Parts

Featuring the most advanced single pass print engine in the binder jetting market, the Shop System offers a turnkey solution for producing complex, end-use metal parts in a fraction of the time and cost of conventional manufacturing and comparably priced legacy AM technologies. The Shop System includes all the equipment machine shops need to begin binder jetting—from printing through sintering—and is designed to scale throughput with a range of build volume configurations. In addition, Desktop Metal software for build preparation and sintering simulation, in combination with metal powders and process parameters optimized to deliver exceptional part quality and repeatability, make it easy for businesses to get up and running with binder jetting in days instead of weeks or months.

Other key Shop System benefits include:

- Easy to use and operate. Designed with the modern machine shop in mind, the Shop System produces parts at the push of a button through its easy-to-use software interface. It features engineered powders and default processing parameters optimized to deliver exceptional quality and ensure repeatability without the need for extensive third party materials qualification or process development. The use of software-generated hand-removable sintering setters eliminates the need for costly and labor-intensive post-processing steps.

- High productivity and superior print quality. Featuring variable build sizes up to 16L and a high-speed, single pass print carriage, the Shop System produces end-use metal parts up to 10 times the speed and at a fraction of the cost of legacy additive manufacturing technologies, amplifying existing output with up to hundreds of complex metal parts printed per day, with mechanical properties exceeding industry standards. With speeds up to 800 cc/hour, the Shop System enables batches of tens or hundreds of complex printed parts in as little as five hours.

- Rich feature detail with exceptional surface finish. Businesses can print dense, complex metal parts with incredibly fine feature detail and surface finishes as low as four-micron roughness average (Ra) out of the furnace. Leveraging an advanced single pass printhead, 1600 native DPI, the Shop System delivers 400 percent the resolution of legacy binder jetting systems. Reliable print quality is enabled by the 5x nozzle redundancy on the printhead — 25 percent higher redundancy than comparable binder jetting systems.

The Shop System also supports 17-4PH stainless steel and chrome cobalt. A broad portfolio of additional materials is in active R&D with additional releases slated to roll out this year.

To learn more about the Shop System and applications for 316L stainless steel, visit https://www.desktopmetal.com/products/shop.

About Desktop Metal

Desktop Metal, Inc., based in Burlington, Massachusetts, is accelerating the transformation of manufacturing with an expansive portfolio of 3D printing solutions, from rapid prototyping to mass production. Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, the company is addressing the unmet challenges of speed, cost, and quality to make additive manufacturing an essential tool for engineers and manufacturers around the world. Desktop Metal was selected as one of the world’s 30 most promising Technology Pioneers by the World Economic Forum and named to MIT Technology Review’s list of 50 Smartest Companies. For more information, visit www.desktopmetal.com.

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks, uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in Desktop Metal, Inc.'s filings with the U.S. Securities and Exchange Commission. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and Desktop Metal, Inc. assumes no obligation and does not intend to update or revise these forward-looking statements, whether as a result of new information, future events, or otherwise.

View source version on businesswire.com: https://www.businesswire.com/news/home/20210824005530/en/

Contacts

Media Relations:

Caroline Legg

carolinelegg@desktopmetal.com

(203) 313-4228

Investor Relations:

Jay Gentzkow

jaygentzkow@desktopmetal.com

(781) 730-2110