I have been working with UV Marble Sheets for many years in export business. When clients visit our factory or ask technical questions, one topic always comes up:

“How exactly are UV marble sheets produced, and why does quality differ so much between suppliers?”

This article is not written from a textbook point of view. It is based on real factory production experience and daily communication with importers and project buyers.

Raw Materials Matter More Than Many People Think

The production of UV marble sheets starts from the base material. Most Uv Marble Panels for interior wall decoration use PVC or SPC as the substrate, mixed with stone powder and additives.

From experience, raw material quality directly affects panel stability. If the calcium powder ratio is not well controlled, the board may become brittle. If recycled material is used excessively, color consistency and surface flatness will suffer.

That is why reliable UV marble sheet manufacturers pay a lot of attention to raw material sourcing, even though it increases cost slightly.

Extrusion Process – The Foundation of Panel Stability

After raw material mixing, the substrate is formed through high-temperature extrusion.

This step looks simple, but it is where many problems begin if not handled properly. Temperature control, extrusion speed, and mold precision all affect thickness tolerance and internal structure.

From export experience, unstable extrusion leads to panels that look fine at first but deform after installation. For UV marble sheets used for interior wall cladding, long-term stability is critical, especially in hot or humid markets.

Surface Printing – Where Appearance Is Decided

Once the substrate is ready, marble patterns are printed on the surface. This is the stage where UV marble sheet appearance is largely defined.

High-quality UV marble panels use high-resolution printing technology to create realistic marble veins. Cheaper products often show blurry patterns or repeated textures, which become obvious when installed on large wall areas.

Many importers focus on price at first, but later realize that surface quality affects the entire project image.

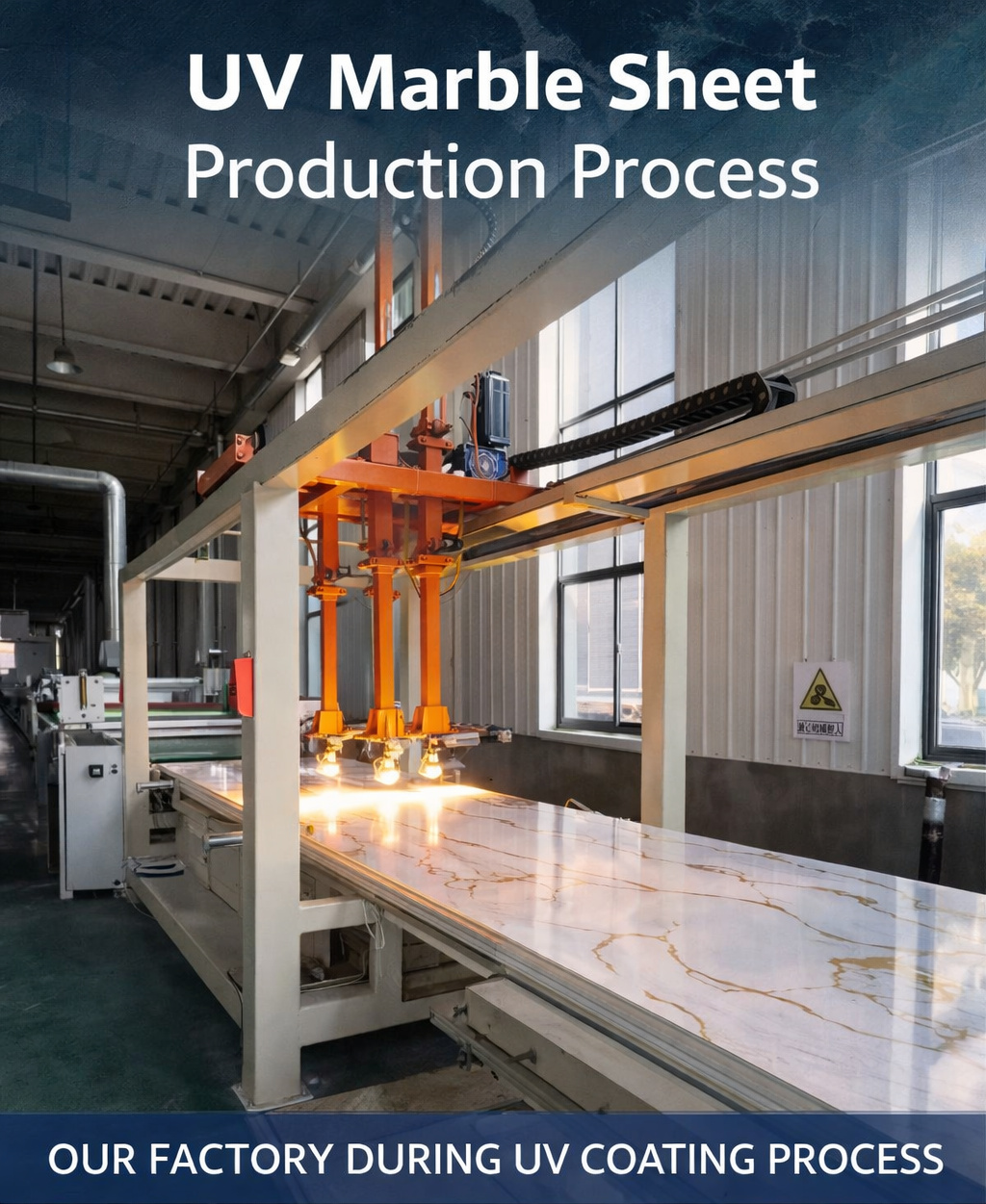

UV Coating Technology – The Core of UV Marble Sheets

The most important step is the UV coating process.

A UV-resistant coating is applied to the surface and cured using ultraviolet light. This creates the glossy finish and protects the printed pattern underneath.

In real production, coating thickness and curing time are critical. Insufficient curing results in poor scratch resistance. Over-curing may cause surface cracking.

Well-controlled UV coating technology improves wear resistance, color stability, and cleaning performance of UV marble wall panels.

Quality Control – The Difference Between Suppliers

From a factory export perspective, quality control is where good suppliers separate themselves from average ones.

Reliable factories check:

- Panel thickness tolerance

- Surface gloss consistency

- Adhesion between coating and substrate

- Color difference between batches

These checks are especially important for importers who need stable quality for repeated orders.

Why Production Process Affects Project Performance

Many clients ask why some UV marble sheets for interior decoration last longer than others.

The answer is simple: production process consistency.

Good raw materials, stable extrusion, precise printing, and proper UV curing together determine whether a panel performs well after installation.

In export markets, especially for hotels and commercial interiors, poor-quality panels lead to complaints, replacements, and project delays.

Practical Advice for Importers

Based on years of cooperation with importers, I usually suggest:

Do not judge UV marble sheets only by surface appearance. Ask about raw materials, extrusion control, and UV coating process.

Choosing a reliable UV marble panel supplier with stable production experience saves more cost in the long run than choosing the lowest price.

Final Thoughts From a UV Marble Sheet Factory

UV marble sheets are not complicated products, but producing stable and consistent quality requires experience and process control.

From a factory point of view, the real value is not just in selling panels, but in helping importers deliver projects smoothly.

That is why more professional buyers now care about how UV marble sheets are made, not just how they look.

Media Contact

Company Name: Shandong Xiangying New Materials Technology Co., Ltd.

Email: Send Email

Phone: +86-13853997002

Country: China

Website: https://www.sdxydecor.com/